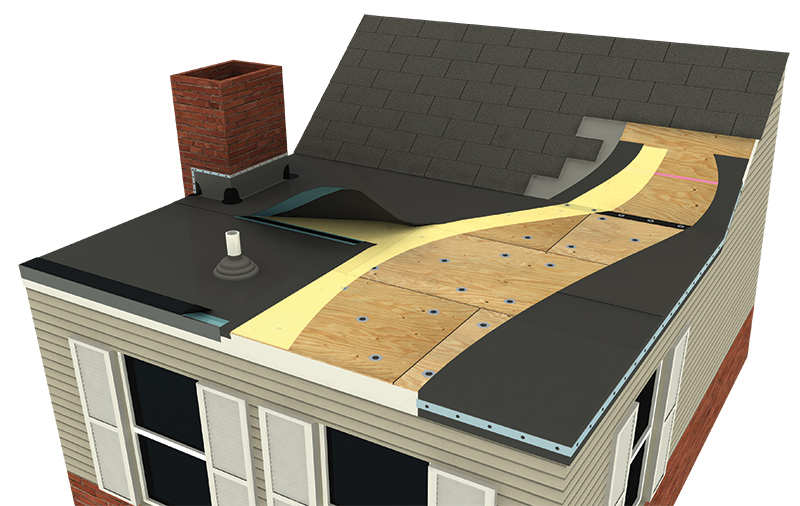

RoofKit EPDM Installation

Installation of RoofKit EPDM rubber roofing can be completed in just a few, easy-to-follow steps. We recommend downloading the Pocket Application Guide as well as reviewing the video segments below to guide you through your installation.

These instructions have been designed to provide you with general descriptions and reference aids for installing the RoofKit fully adhered roof system, but are not intended to be all-inclusive. Should you have questions or encounter a situation that is not covered in these instruction materials, please call 1-800-225-4714, extension 7889, for technical support. Or visit the Contact Us and Frequently Asked Questions pages of our website.

Pocket Application Guide:

Pocket Application Guide:

• Designed to give a general description of a

RoofKit fully adhered roof system

• Intended to be used as a reference aid only

for EPDM Membrane RoofKit Roofing installation

• Use in conjunction with EPDM Membrane

RoofKit Instructional Videos

Related Links

![]()

» FREQUENTLY ASKED QUESTIONS

![]()

» MATERIAL SAFETY DATA SHEETS

![]()

» SPECIFICATION DETAILS

![]()

» CONTACT US

Installation Videos:

Introduction

Step 1: Preparing the Roof Surface

Step 2: Layout & Measurement of Material

Step 3: Adhering the EPDM Membrane

Step 4: Preparing the Seam Area

Step 5: Completing the Seam

Step 6: Completing Edge Details

Detail: Perimeter Edge Metal

Detail: Inside and Outside Corners

Detail: Applying a Patch

Detail: Installing a Pipe Boot

Detail: Vertical and Angled Walls